| HIRANUMA APPLICATION DATA | Karl Fischer Titrator | Data No. | KF18 | Nov.29. 2018 |

| Water contents | Validation test with water standard KF Coulometry – Heat evaporation method |

1. Abstract

A heat evaporation method using Karl Fischer titrator combined with solid evaporator is suitable for insoluble sample in anode solution, such as plastics and inorganic compounds. The measurement of with the heat evaporation method is carried out by heating the sample while a carrier gas is blown into the evaporation chamber and introducing the evaporated moisture together with the carrier gas into the electrolysis cell.

This application introduces an example of measurement of solid water standard for validation of titrator system with solid evaporator.

2. Apparatus and Reagents

| (1) | Apparatus for heat evaporation method | ||

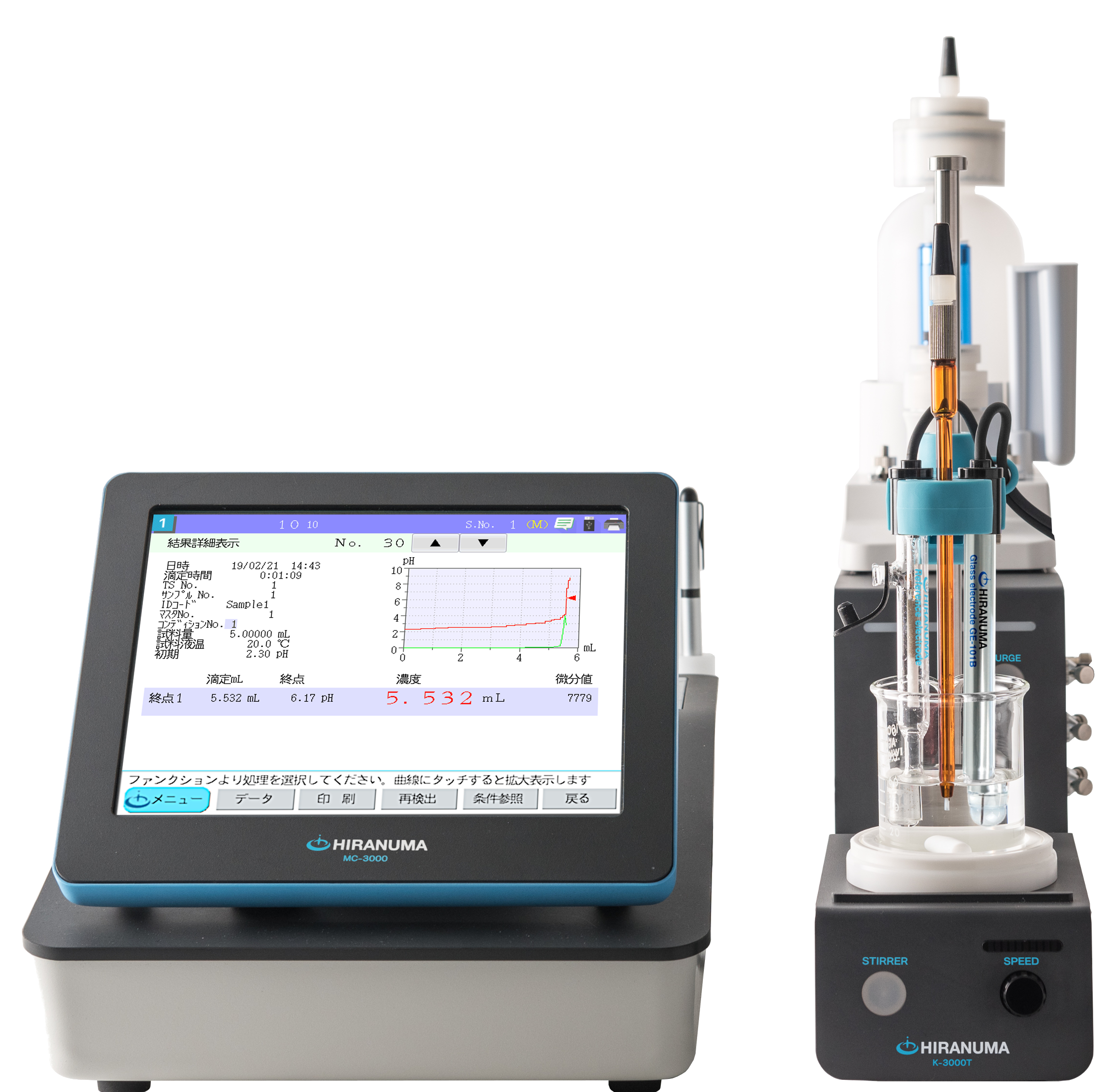

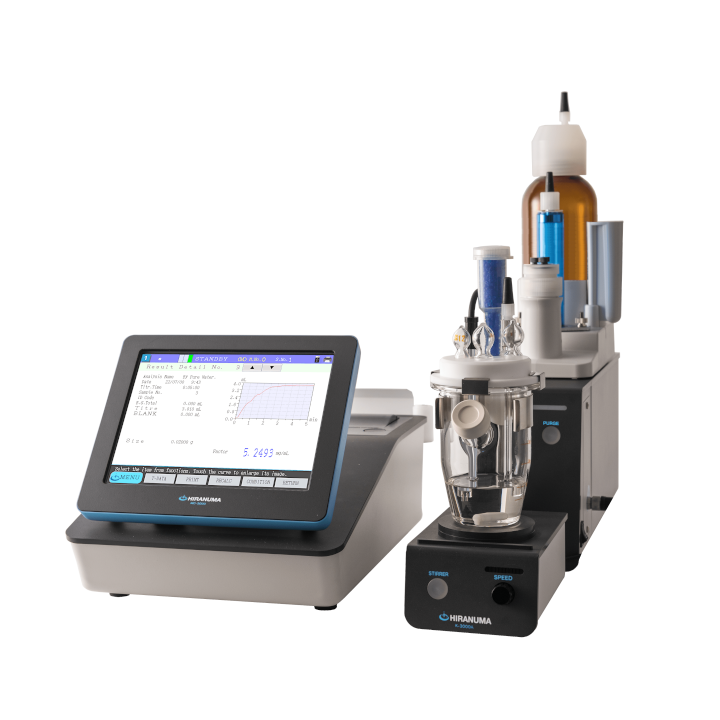

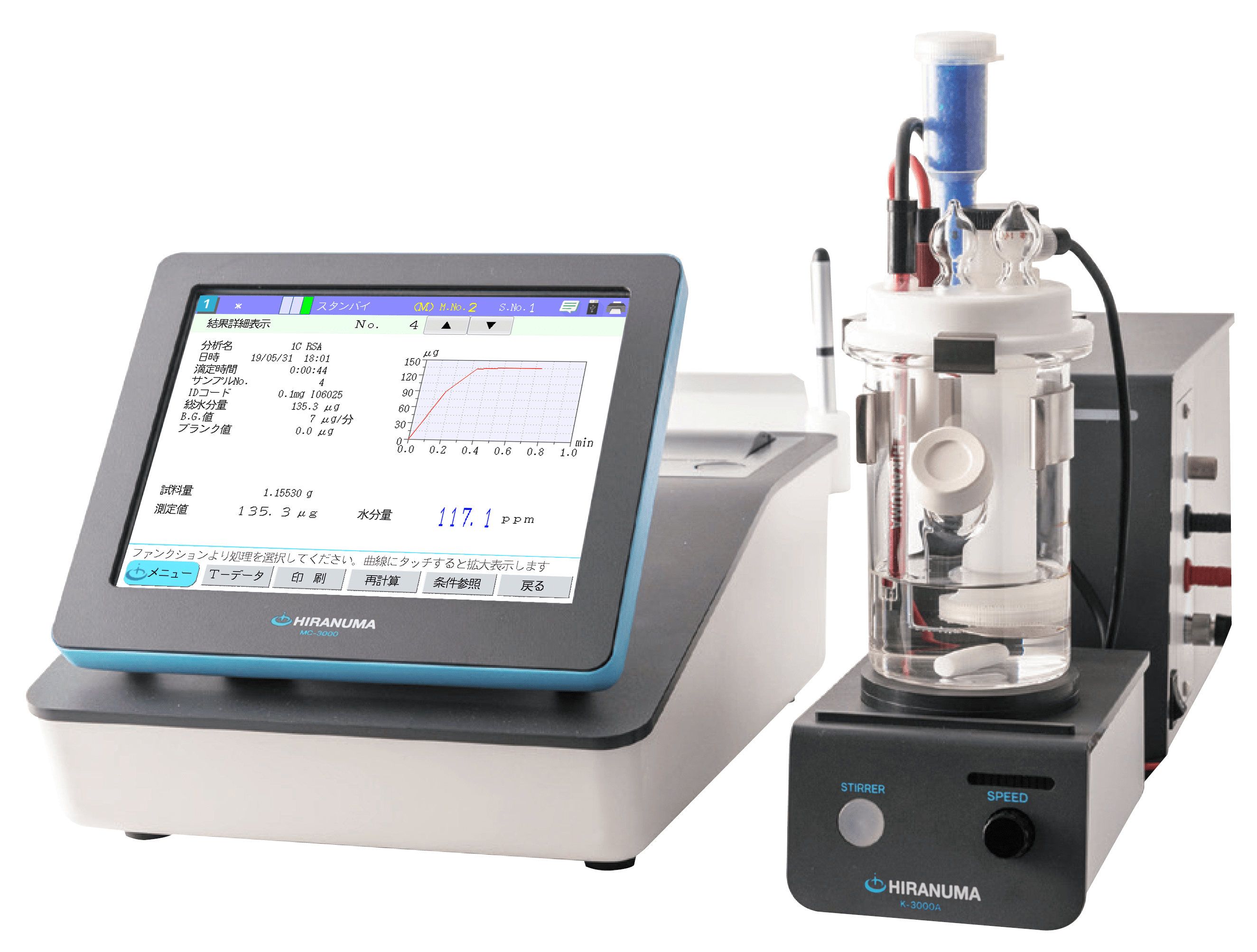

| Titrator | : | HIRANUMA Karl Fischer Coulometric titrator AQ-series or MOICO-A19 | |

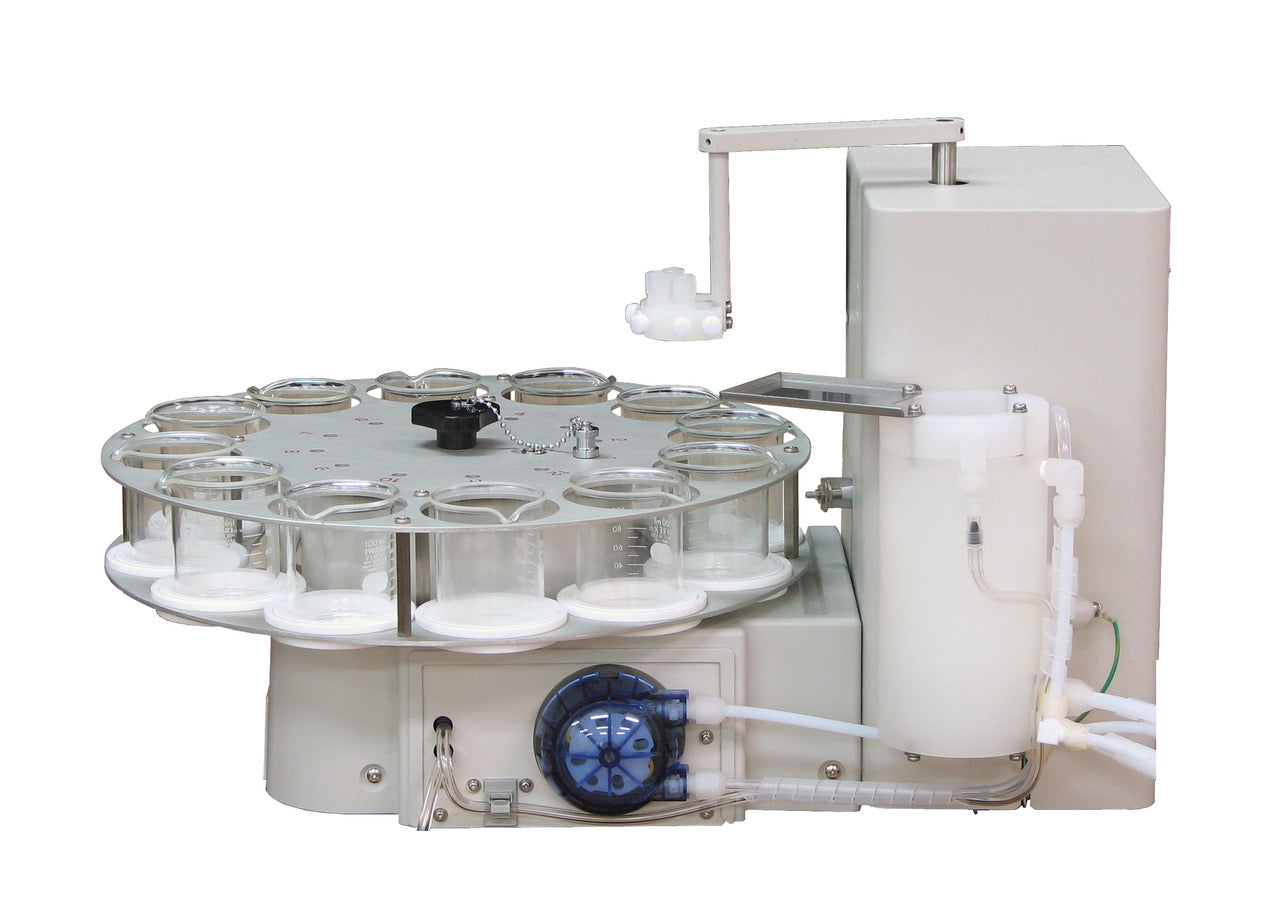

| Evaporator | : | Hiranuma Solid Evaporator EV-2000 | |

| Electrolytic cell | : | Standard Cell Fritless Cell (No cathode solution required) |

|

| (2) | Reagents | ||

| Anode solution | : | HYDRANAL Coulomat AG | |

| Cathode solution | : | HYDRANAL Coulomat CG | |

| Dehydrated methanol | : | HYDRANAL Methanol | |

| Carrier gas | : | Nitrogen gas (Dew Point : -65 ℃ or less) | |

| (3) | Water standard material | ||

| (i) HYDRANAL- Standard sodium tartrate dihydrate (Honeywell) CoA : 15.64 %(*¹), Permissible range of recovery rate : ± 5 %(*²), Heat temperature : 160 °C (ii) HYDRANAL- Water Standard KF-Oven, 140-160°C (Honeywell) CoA : 5.04 %(*¹) , Permissible range of recovery rate : ± 4 %, Heat temperature : 140 – 160 °C (iii) Water Standard Oven 1 % (Merck) CoA : 0.99 %(*¹) , Permissible range of recovery rate : ± 3 %, Heat temperature : 140 – 400 °C (*1) CoA values described in the test report are different with each production lot. (*2) Permissible range of standard material (i) is set to our own criterion for inspection of evaporator, not described on the document of this standard. |

|||

3. Procedure

| (1) | Fill 100 mL of anode solution and 50 mL of dehydrated methanol into anode compartment. Fill one ampoule of cathode solution into cathode compartment (Fig.3.1). When fritless cell is used, cathode solution is not necessary. |

| (2) | Start blanking to attain stable background. |

| (3) | Flow N2 carrier gas with flow rate 200 mL/min. |

| (4) | Set the formed aluminum foil into the evaporation chamber of EV-2000 (Fig.3.2). |

| (5) | Connect electrolytic cell and evaporation chamber with tube (Fig.3.3). |

| (6) | Blanking become stable and then start pre-heating at set temperature. |

| (7) | After the pre-heating procedure finished, confirm blanking stable with carrier gas flowing. |

| (8) | Make formed aluminum foil to use balance dish. |

| (9) | Weigh the sample on the aluminum foil. Weighing amounts are approximately 0.05 g for standard material (i), 0.1 g for standard material (ii) and 0.2 g for standard material (iii). |

| (10) | Put the sample with aluminum foil into evaporation chamber from stopper of the chamber. |

| (11) | Start titration. Measurement parameter is shown in Table 4.1. |

| (12) | Blank measurement is also performed with same procedure except for sample addition. |

Fig.3.1. Preparation of the reagents. (Standard Cell)

Fig.3.2. Forming the aluminum foil.

Fig.3.3. Schematic diagram of heat evaporation method.

4. Parameters and results

Table 4.1 Parameters for heat evaporation method.

| Condition File | ||

| Cal Mode | 0:Sample weight(net) | |

| X=(H₂O-BLANK)/SIZE | ||

| Interval Time | 30 | sec |

| Current | MEDIUM | |

| Min.Timer | 5 | min |

| Blank Value | 0 | µg |

| Unit Mode | AUTO | |

| Auto Interval | 0 | g |

| Minimum Count | 5 | µg |

| Back Ground | ON | |

| Sample Size Input | Every Time | |

| *Cell Type | Stadard/Fritless |

| EV.File | ||

| * Step 1 Temp. | 160 | ℃ |

| Time | 0 | min |

| Step 2 Temp. | 0 | ℃ |

| Time | 0 | min |

| Step 3 Temp. | 0 | ℃ |

| Time | 0 | min |

| Pre. Heat End Time | 5 | min |

| End B.G. | 0 | μg |

| Cooling Time | 5 | min |

| B.G. Count | 60 | |

| Back Purge Time | 5 | sec |

(* Set the electrolytic cell and heating temperature appropriately.)

Table 4.3 Results of water content measurement of water standard.

| Water Standard |

Temp. (°C) |

Cell | No. | Sample Size (g) |

Water (μg) |

Water Content(%) |

Statistics Results | Recovery rate(%) |

|

| (i) | 160 | Standard | 1 | 0.0529 | 8149.4 | 15.4053 | Avg. | 15.418 % | 98.6 |

| 15.64% | 2 | 0.0615 | 9506.1 | 15.4571 | SD | 0.035 % | |||

| 3 | 0.0527 | 8110.6 | 15.3901 | RSD | 0.23 % | ||||

| Fritless | 1 | 0.0216 | 3327.3 | 15.4042 | Avg. | 15.436 % | 98.7 | ||

| 2 | 0.0378 | 5853.4 | 15.4852 | SD | 0.043 % | ||||

| 3 | 0.0577 | 8896.3 | 15.4182 | RSD | 0.28 % | ||||

| (ii) | 150 | Standard | 1 | 0.1426 | 7242.6 | 5.0790 | Avg. | 5.083 % | 100.8 |

| 5.04% | 2 | 0.1406 | 7181.3 | 5.1076 | SD | 0.023 % | |||

| 3 | 0.1180 | 5973.0 | 5.0619 | RSD | 0.45 % | ||||

| Fritless | 1 | 0.1430 | 7294.1 | 5.1008 | Avg. | 5.088 % | 100.9 | ||

| 2 | 0.1011 | 5143.9 | 5.0879 | SD | 0.013 % | ||||

| 3 | 0.1080 | 5479.9 | 5.0740 | RSD | 0.26 % | ||||

| (iii) | 300 | Standard | 1 | 0.1236 | 1240.1 | 1.0033 | Avg. | 1.007 % | 101.7 |

| 0.99% | 2 | 0.1223 | 1230.4 | 1.0061 | SD | 0.004 % | |||

| 3 | 0.1523 | 1539.0 | 1.0105 | RSD | 0.36 % | ||||

| Fritless | 1 | 0.2661 | 2668.6 | 1.0029 | Avg. | 1.005 % | 101.6 | ||

| 2 | 0.2372 | 2391.3 | 1.0081 | SD | 0.003 % | ||||

| 3 | 0.2419 | 2431.8 | 1.0053 | RSD | 0.26 % | ||||

5. Note

| (1) | Validation test of titrator with solid evaporator is evaluated from the recovery rate of the result with respect to the CoA value written in the test report of the water standard. Permissible range of recovery rates differed depending on the type of water standard materials. The recovery rate of standards (i), (ii) and (iii) should fall within the range of ± 5 %, ± 4 % and ± 3 % respectively. | ||||

| (2) | Select the type of water standard that is close to the water content or heating temperature of your actual sample. | ||||

| (3) | The optimized electrolysis control for fritless cell of AQ series released after 2009 improves the measurement accuracy of fritless cell. It can be used with the evaporator as well. Suitable reagent for fritless cell is required. For example, Hydranal coulomat AG and AG-Oven are compatible with fritless cell. | ||||

| (4) | When nitrogen gas for carrier gas is not available, optional a dry air pump for EV-2000 can be used to supply air carrier gas. When using air as a carrier gas, pay attention to the following points.

|

| Keywords: | Karl Fischer, Coulometric titration, Heat evaporation, Water standard, Validation, Fritless cell |