| HIRANUMA APPLICATION DATA | Automatic Titrator | Data No. | L5 | Oct. 7,2022 |

| Lubricant petroleum products | Acid number in Refrigerating machine oil |

1. Abstract

Refrigerating machine oil is used in a state mixed with refrigerant such as hydrofluorocarbon. The official standard of refrigerant (e.g. JIS K 2211) specifies the acid number test according to JIS K 2501. It is indicated by “milligrams of potassium hydroxide required to neutralize acidic components contained in 1 g of the sample”.

In this article, we apply the color-indicator titration method described in JIS K2501 to automatic titrator, and introduce measurement of acid number in refrigerating machine oil by photometric titration. Acid and base number with color-indicator titration is also regulated in ASTM D974. p-Naphtholbenzein is used as color indicator.

2. Configuration of instruments and Reagents

| (1) | Configuration of instruments | ||

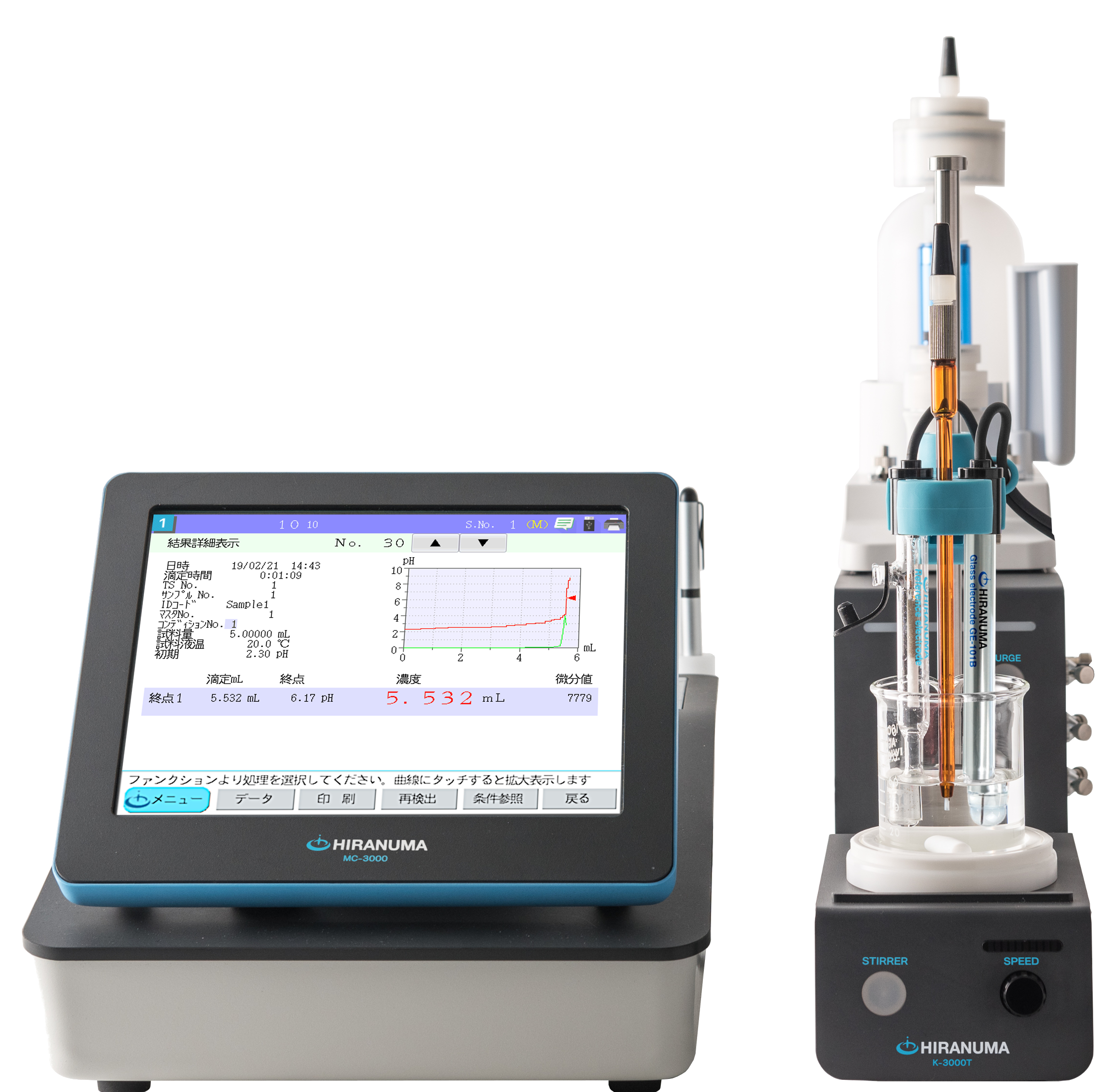

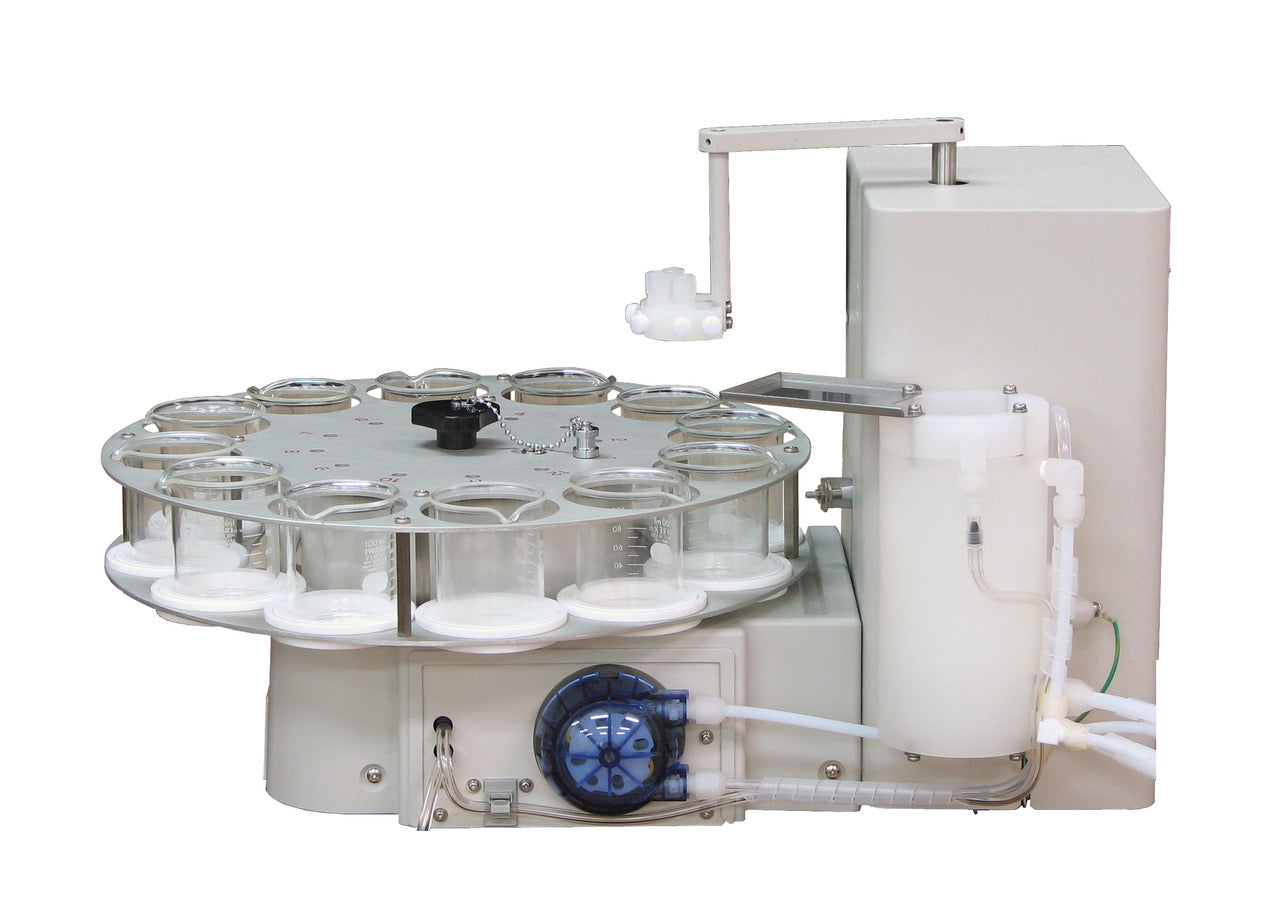

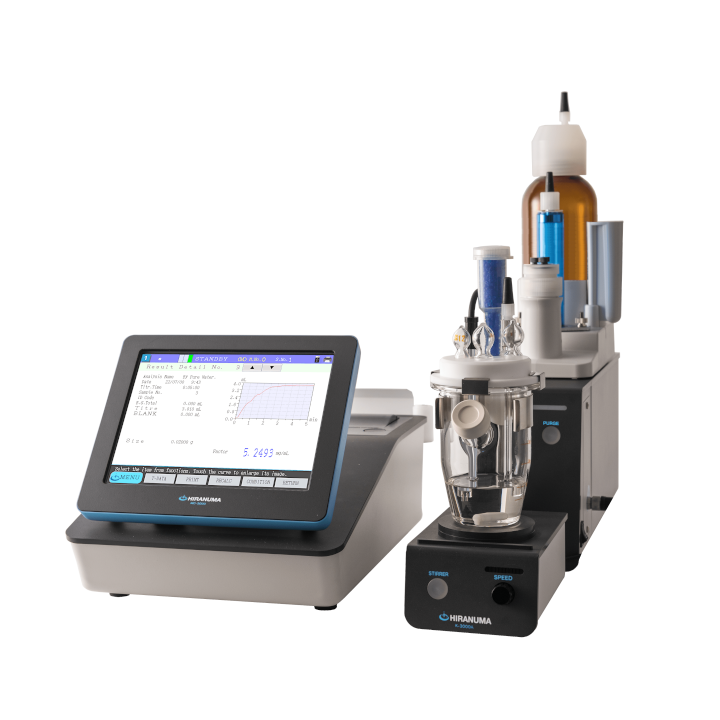

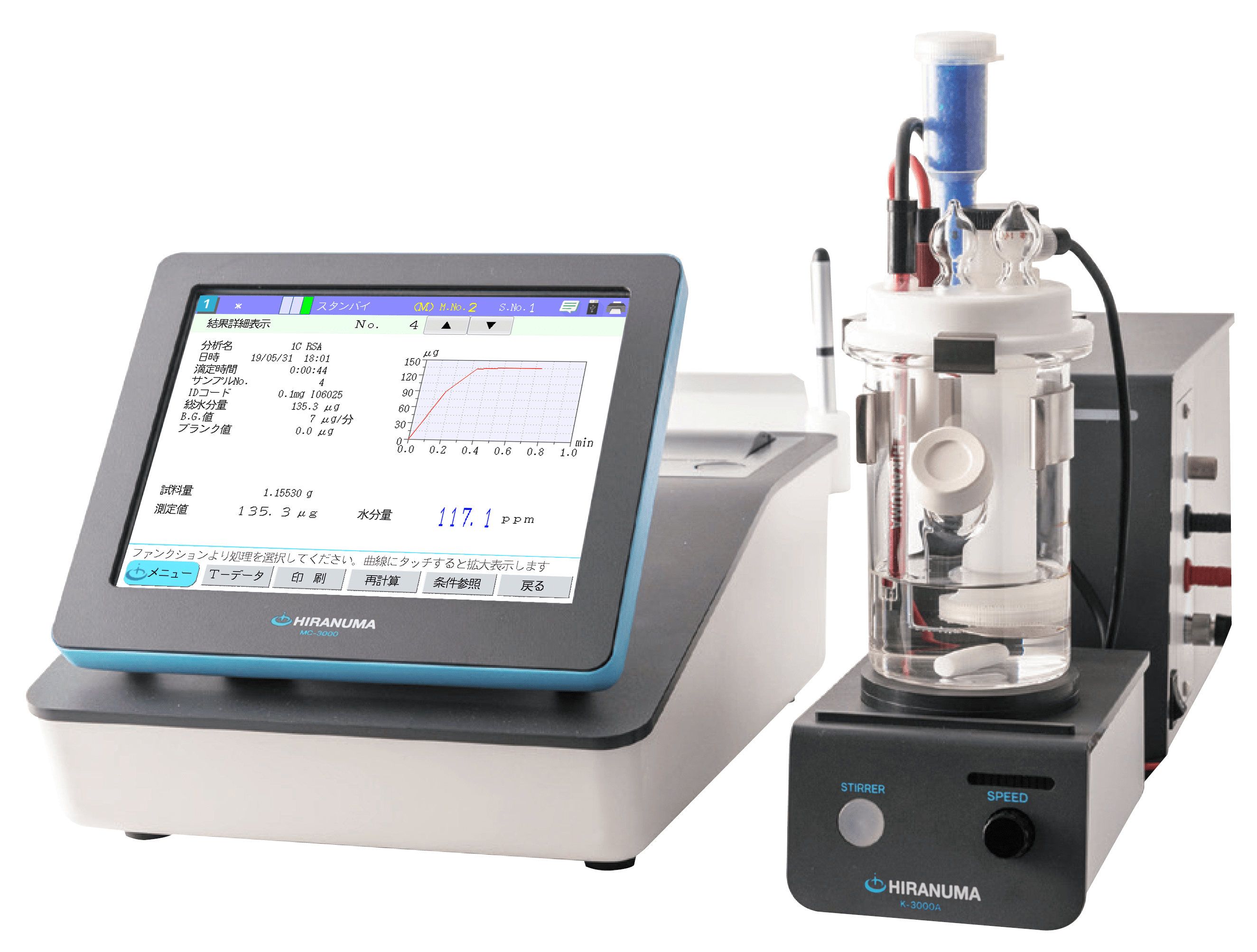

| Main unit | : | Hiranuma automatic titrator COM Series with photometric unit M type | |

| Electrode | : | Interference filter 650 nm | |

| (2) | Reagents | ||

| Titrant | : | 0.1 mol/L potassium hydroxide in 2-propanol | |

| Titration solvent | : | Mixture of 500 mL of Toluene, 495 mL of 2-propanol and 5 mL of water | |

| Indicator | : | 1 g of p-naphtholbenzein dissolved in 100 mL of titlation solvent | |

3. Measurement procedure

| (1) | Take 20 g of sample into 200 mL tall beaker and weigh accurately to 0.1 mg digits. Note that the weight of sample will be changed depending on the acid number. |

| (2) | Add 100 mL of titration solvent and dissolve sample by stirrer. The stirrer speed must be adjusted to avoid the scattering of contents or taking the air into the solution. |

| (3) | Immerse the electrodes and titrate by alcoholic KOH titrant. Also, perform the blank test with the same procedure of sample measurement. |

4. Measurement conditions and results

Examples of titration conditions

Measurement of blank

| Cndt No. | 37 | |

| Method | B-Cross | |

| Buret No. | 1 | |

| Amp No. | 2 | |

| D. Unit | T% | |

| S-Timer | 60 | sec |

| C.P. mL | 0 | mL |

| T Timer | 0 | sec |

| D.P. mL | 0 | mL |

| End Sens | 1000 | |

| Over mL | 0.3 | mL |

| Max.Vol. | 1 | mL |

| ConstantNo. | 37 | |

| Size | 0 | g |

| Blank | 0 | mL |

| Molarity | 0.1 | mol/L |

| Factor | 0.9775 | |

| K | 56.1 | |

| L | 0 | |

| Unit | mL | |

| Formula | D | |

| Digits | 4 | |

| Auto In Pram. | Non | |

| Mode No. | 41 | |

| Int Time Max | 60 | sec |

| Del K | 0 | |

| Del Sens | 0 | mV |

| Int Time | 10 | sec |

| Int Sens | 20 | mV |

| Brt Speed | 2 | |

| Pulse | 8 |

Measurement of sample

| Cndt No. | 38 | |

| Method | B-Cross | |

| Buret No. | 1 | |

| Amp No. | 2 | |

| D. Unit | T% | |

| S-Timer | 60 | sec |

| C.P. mL | 0 | mL |

| T Timer | 0 | sec |

| D.P. mL | 0 | mL |

| End Sens | 1000 | |

| Over mL | 0.5 | mL |

| Max.Vol. | 20 | mL |

| ConstantNo. | 38 | |

| Size | 20.059 | g |

| Blank | 0.123 | mL |

| Molarity | 0.1 | mol/L |

| Factor | 0.9775 | |

| K | 56.1 | |

| L | 0 | |

| Unit | mg/g | |

| Formula | (D-B)*K*F*M/S | |

| Digits | 4 | |

| Auto In Pram. | Non | |

| Mode No. | 42 | |

| Int Time Max | 60 | sec |

| Del K | 0 | |

| Del Sens | 0 | mV |

| Int Time | 10 | sec |

| Int Sens | 20 | mV |

| Brt Speed | 2 | |

| Pulse | 20 |

Measurement results

Measurement of blank

| Measurement number |

Size (g) |

Titer (mL) |

|---|---|---|

| 1 | – | 0.123 |

| 2 | – | 0.122 |

| Average | 0.123 mL |

Measurement of sample

| Measurement number |

Size (g) |

Titer (mL) |

Base number (mgKOH/g) |

|---|---|---|---|

| 1 | 20.0590 | 0.151 | 0.0077 |

| 2 | 20.0084 | 0.157 | 0.0093 |

| Average | 0.0085 mgKOH/g |

Examples of measurement curves

|

|

| Measurement of blank | Measurement of sample |

5. Note

| (1) | Management of the photometric probe As the probe is used, it becomes dirty on light path and the transmittance decreases. Therefore it is necessary to wipeout adherents with soft cloth on regular bases. |

| (2) | Maintenance of buret It is recommended to wash the flow channel of buret with water. This is because alcoholic KOH titrant have a tendency toward crystallization. When not using for a long time, please discharge titrant and then wash flow channel with water. |

| (3) | End point detection When the endpoint is not detected sharply, it may be due to the absorption of carbon dioxide. In this case, purging nitrogen gas in the head space of the beaker improves end point detection. |

| Keywords: | JIS K2211, JIS K2501, ASTM D974, Refrigerating machine oil, Refrigerant, Acid number, Color indicator titration, Photometric titration. |