| HIRANUMA APPLICATION DATA | Automatic Titrator | Data No. | L2 | Oct. 7,2022 |

| Lubricant petroleum products | Base number in lubricating oil (Hydrochloric acid method) |

1. Abstract

The base number of lubricant oil is one of the important index for judging its quality. Measurement of base number is defined in several standard test methods. It is indicated by “milligrams of potassium hydroxide equivalent weight to acid required to neutralize basic components contained in 1 g of the sample”. There are two methods of base number, hydrochloric acid method and perchloric acid method. In this article, hydrochloric acid method will be introduced. The international standard methods for base number with hydrochloric acid method are shown as bellow.

・ JIS K2501 2003:Petroleum products and lubricants – Determination of neutralization number

・ ASTM D4739-2011:Standard Test Method for Base Number Determination by Potentiometric Hydrochloric Acid Titration

The potentiometric titration process is as follows:

1) Weigh sample exactly corresponding to base number and dissolve it in a titration solvent.

2) Immerse glass electrode and reference electrode.

3) Start titration with alcoholic hydrochloric acid solution.

Inflection point is defined as the end point if it obtained sharply. If it’s not clear, the pH obtained from measurement of buffer solution is defined as the end point. The measurement with the latter end point detection will be introduced here.

2. Configuration of instruments and Reagents

| (1) | Configuration of instruments | ||

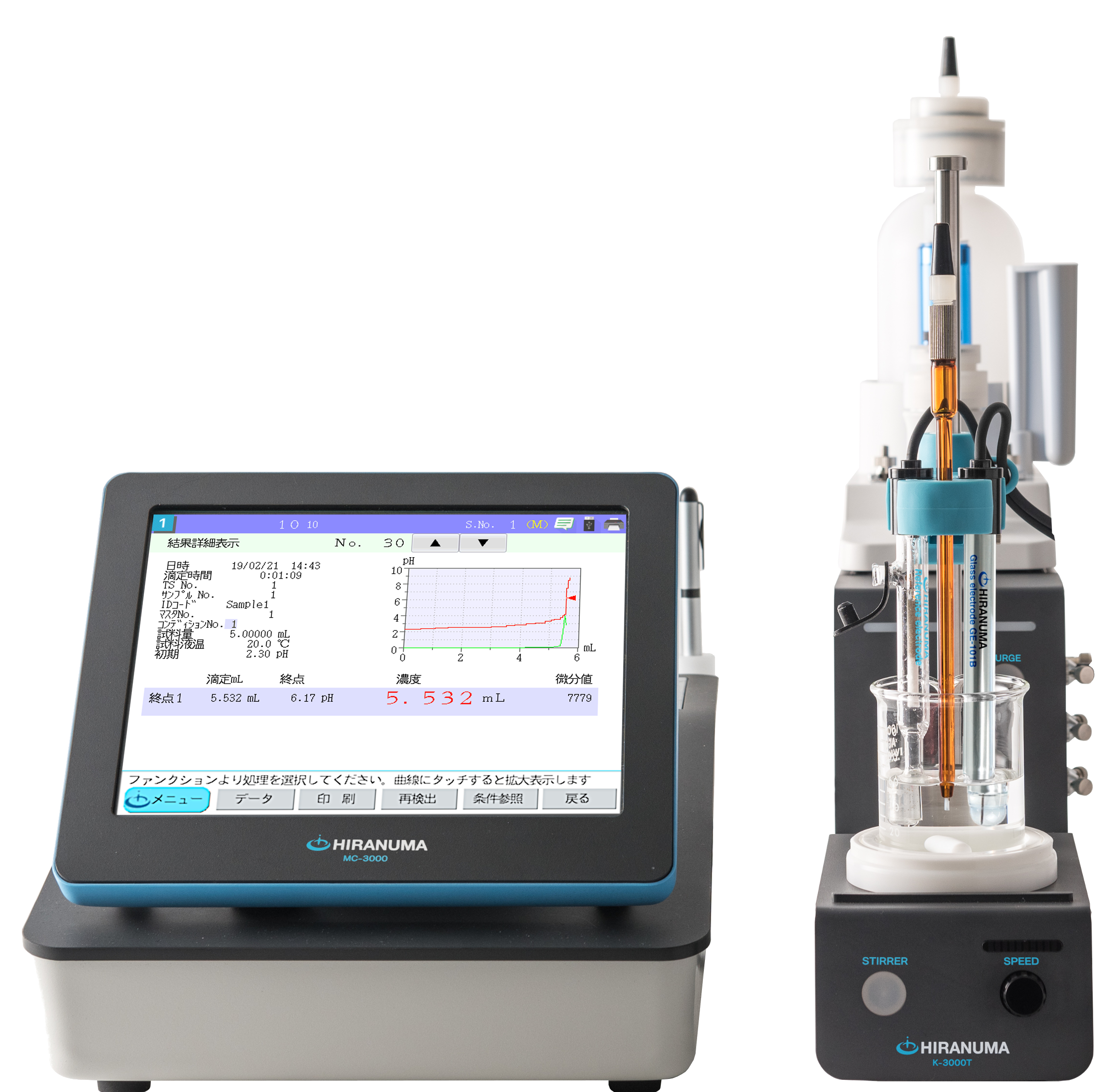

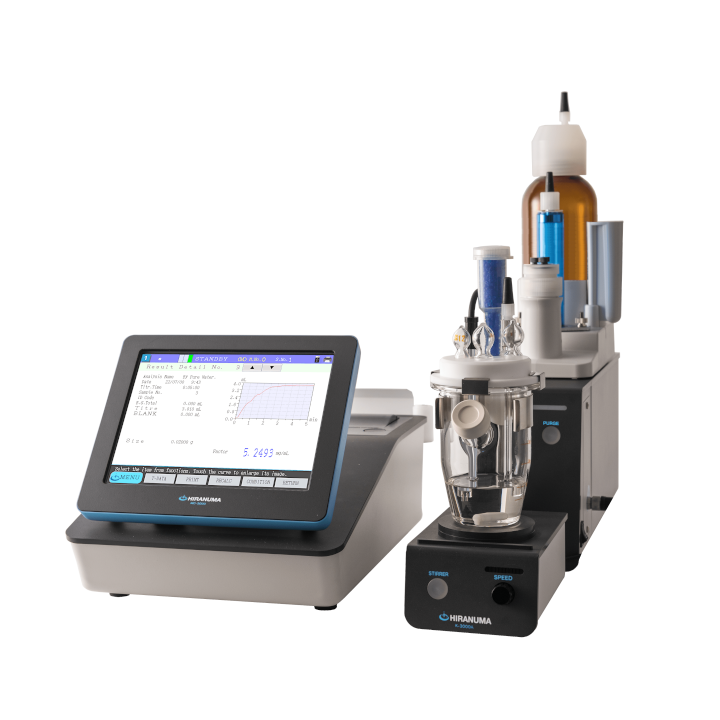

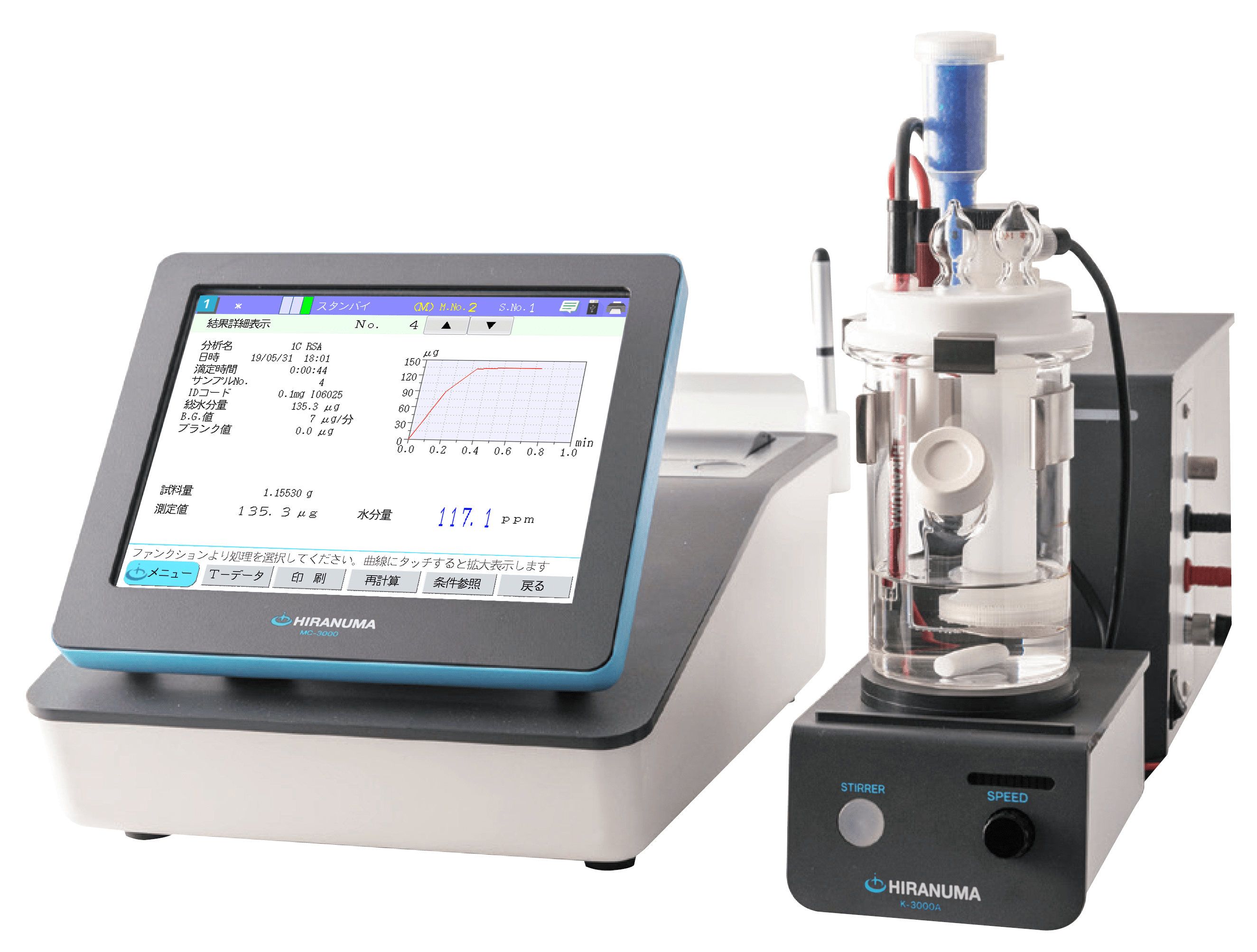

| Main unit | : | Hiranuma Automatic Titrator COM Series | |

| Electrode | : | Glass electrode GE-101B | |

| : | Reference electrode RE-201Z | ||

| : | Thermistor electrode TE-403 | ||

| (2) | Reagents | ||

| Titrant | : | 0.1 mol/L hydrochloric acid in 2-propanol | |

| Titration solvent | : | Mixture of 500 mL of Toluene, 495 mL of 2-Propanol and 5 mL of water | |

| Buffer | : | Mixture of 10 mL of “Buffer A” and 100 mL of titration solvent, “Buffer A” is regulated in “JIS K 2501” | |

3. Measurement procedure

| (1) | Determination of the end point pH

|

||||||

| (2) | Measurement of Base number

|

4. Measurement conditions and results

Examples of titration conditions

Measurement of blank

| Cndt No. | 47 | |

| Method | Set | |

| Buret No. | 1 | |

| Amp No. | 1 | |

| D. Unit | pH | |

| S-Timer | 120 | sec |

| C.P. mL | 0 | mL |

| Direction | ↓ | |

| T Timer | 0 | sec |

| D.P. mL | 0 | mL |

| End Point pH | 3.71 | pH |

| Over mL | 0.1 | mL |

| Max.Vol. | 20 | mL |

| ConstantNo. | 47 | |

| Size | 0 | g |

| Blank | 0 | mL |

| Molarity | 0.1 | mol/L |

| Factor | 0.9985 | |

| K | 0 | |

| L | 0 | |

| Unit | mL | |

| Formula | D | |

| Digits | 3 | |

| Auto In Pram. | Non | |

| Mode No. | 15 | |

| Int Time Max | 0 | sec |

| Del K | 0 | |

| Del Sens | 0 | mV |

| Int Time | 60 | sec |

| Int Sens | 0 | mV |

| Brt Speed | 2 | |

| Pulse | 40 |

Measurement of sample

| Cndt No. | 48 | |

| Method | Oil1 | |

| Buret No. | 1 | |

| Amp No. | 1 | |

| D. Unit | pH | |

| S-Timer | 120 | sec |

| C.P. pH | 6 | pH |

| Direction | ↓ | |

| T Timer | 0 | sec |

| D.P. pH | 6 | pH |

| End Point pH | 3.71 | pH |

| Over mL | 0.3 | mL |

| Max.Vol. | 20 | mL |

| ConstantNo. | 48 | |

| Size | 5.0066 | g |

| Blank | 0.018 | mL |

| Molarity | 0.1 | mol/L |

| Factor | 0.9985 | |

| K | 56.1 | |

| L | 0 | |

| Unit | mg/g | |

| Formula | (D-B)*K*F*M/S | |

| Digits | 3 | |

| Auto In Pram. | Non | |

| Mode No. | 11 | |

| Del mL | 0.2 | mL |

| Int Time1 | 60 | sec |

| Tran Timer | 120 | sec |

| Del mL2 | 0.05 | mL |

| Int Time2 | 60 | sec |

| Int Time | 0 | sec |

| Int Sens | 0 | mV |

Measurement results

Measurement of blank

| Number of Measurement |

Size (g) |

Titer (mL) |

|---|---|---|

| 1 | – | 0.020 |

| 2 | – | 0.015 |

| Avg. (Blank) |

0.018 mL | |

Measurement of sample

| Number of Measurement |

Size (g) |

Titer (mL) |

Base number (mgKOH/g) |

|---|---|---|---|

| 1 | 5.0066 | 1.786 | 1.978 |

| 2 | 5.0291 | 1.770 | 1.951 |

| 3 | 5.0086 | 1.747 | 1.934 |

| Statistic calculation |

Avg. SD RSD |

1.95 mgKOH/g 0.022 mgKOH/g 1.14 % |

|

Examples of measurement curves

|

|

| Measurement of blank | Measurement of sample |

5. Note

| (1) | Management of electrode |

| It is recommended to activate the electrodes for about 5 minutes to pure water for each measurement. This is because when glass electrode is used for a long time in a nonaqueous solvent, the response speed and electromotive force decrease. Also potassium chloride crystallizes around the liquid junction of the reference electrode, which causes pH fluctuation. | |

| (2) | Maintenance of buret |

| When you do not use the equipment for a long time, it is recommended to wash the flow channel of buret with water. |

| Keywords: | JIS K2501, ASTM D4739, Lubricant oil, Neutralization number, Base number, Potentiometric titration, Non-aqueous neutralization titration |

*Some measurement would not be possible depending on optional configuration of system.