Description

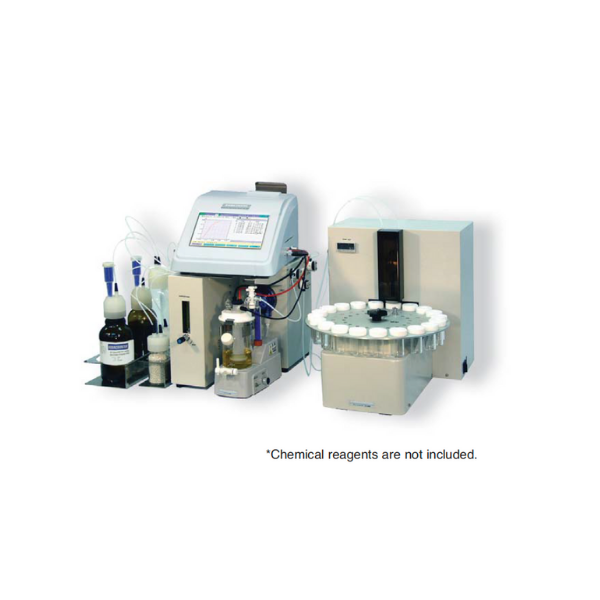

The Aquacounter AQS/AQL-22320 automated oil evaporator system is an automated Karl Fischer titrator system consisting of the AQ-2200 (coulometric titrator) and the EV-2000L (oil evaporator) units.

The system is designed for analyzing moisture in difficult samples such as shale oil crude oil, grease, heavy lubricants, other oils and other difficult samples. Using an azeotropic distillation solvent like toluene or xylene, moisture can be evaporated at a lower temperature thus saving on expensive Karl Fisher reagents and lower maintenance costs since the titration cell remains clean and free of contaminants.

The automated system allows the analyst to load the samples into the glass vials and then place the glass vials on the sample tray of the system. The operator only needs to push the “start” button once to begin the analyses.

Features

- Sample changer holds up to 20 vials.

- Equipped with Automatic KF reagent exchanging function.

- Wide temperature setting covers the full range of azeotropic points.

- Reduces costs for KF reagent and waste disposal.

- Can process large numbers of samples.

- Manufactured by Hiranuma in Japan

|

ITEM |

Solid Evaporator SE-320 |

|

Number of sample vials |

20 positions |

|

Volume of sample vial |

Max. 3 mL |

|

Seal |

PTFE cap with PTFE septum |

|

Carrier gas |

Nitrogen gas* *Optional N2 gas generator from JMS is recommended |

|

Carrier gas flow rate |

50 - 300mL/min |

|

Carrier gas desiccant |

Molecular Sieves |

|

Heater |

Aluminum block |

|

Heating temperature |

Room temperature to 200C |

|

Power supply / Power consumption |

AC100 - 240V, 50/60Hz, 150VA |

|

Dimensions |

Sample changer + heater unit: 350 (W) x 510 (D) x 390 (H) mm Valve unit: 275 (W) x 440 (D) x 280 (H) mm |

|

Weight |

Sample changer + heater unit: Approx. 19kg Valve unit: Approx. 9kg |